What are active carbon sources?

Active carbon sources, also known as activated carbon or activated charcoal sources, refer to materials that have undergone a specific activation process, resulting in a highly porous form of carbon with a large surface area. This activation process involves treating carbon-rich materials at high temperatures, often in the presence of gases like steam or carbon dioxide, which creates a network of pores and increases the surface area available for adsorption.

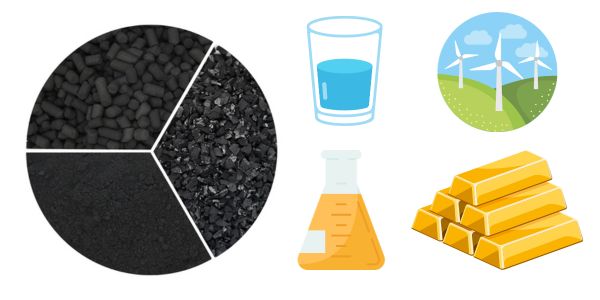

Various carbon-rich materials can be used as sources for activated carbon, including:

Coconut shells: Activated carbon derived from coconut shells is widely used due to its high porosity and adsorption capacity. The coconut shell is heated and activated to create the activated carbon.

Wood: Certain types of wood, such as hardwoods like oak or softwoods like pine, can be processed into activated carbon through controlled heating and activation.

Coal: Certain grades of coal, like bituminous or lignite, can undergo activation processes to produce activated carbon.

Agricultural residues: Materials like sawdust, rice husks, and other agricultural byproducts can also be utilized to create activated carbon through specific activation methods.

What is the function of active carbon?

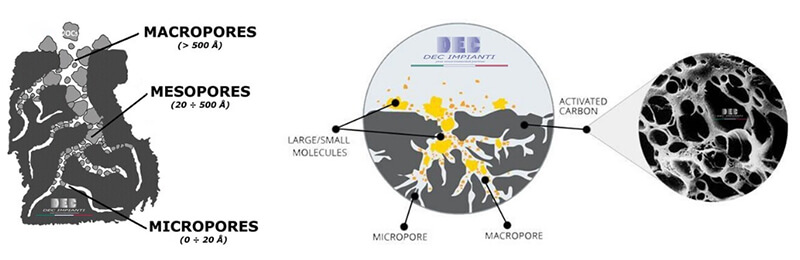

Activated carbon functions primarily through adsorption. Its porous structure and large surface area enable it to attract and trap molecules and impurities from gases or liquids.

· Water Treatment: Activated carbon acts as a sponge, attracting and trapping impurities like organic compounds, chlorine, and pollutants from water.

· Air Purification: Similar to its action in water, activated carbon absorbs gases and odors from the air, effectively cleansing indoor environments.

· Solvent Recovery: In industrial settings, activated carbon acts as a collector, reclaiming solvents from liquids.

· Gold Extraction: Activated carbon plays a vital role in the extraction of gold by attracting and holding onto microscopic gold particles in mining processes.

· Food and Beverage Processing: Employed as a purifier, activated carbon refines food products by eliminating colorants, undesirable flavors, and impurities from liquids like syrups, juices, and oils.

How does active carbon work?

Activated carbon works primarily through a process called adsorption. Its porous structure contains a lot of tiny pores and a large surface area that attracts and traps molecules of gases, liquids, or dissolved substances when they come into contact with the activated carbon. This adsorption occurs as the impurities or molecules adhere to the surface of the activated carbon due to various attractive forces. So, the activated carbon effectively removes or reduces the concentration of these impurities from the surrounding medium, purifying liquids or gases in processes such as water treatment, air purification, or other applications where purification or removal of contaminants is necessary.

Conclusion about active carbon

Activated carbon stands as a cornerstone of purification and filtration solutions in our life. Zhulin Carbon dedicates to producing top-quality activated carbon is evident in its commitment to innovation and sustainable practices. Cooperate with Zhulin Carbon, let's help your activated carbon business better and large.FAQ about active carbon:

What does active carbon do in aquarium?

Activated carbon is often used together with filter materials, such as zeolite, volcanic rock, etc. Activated carbon can absorb impurities, pollutants, and organic compounds in the water, which helps in improving water clarity and eliminating toxins that could harm the aquatic life within the aquarium. Besides, it's essential to regularly replace activated carbon as its adsorption capacity diminishes over time, ensuring its continual effectiveness in maintaining a healthy and balanced aquatic environment.

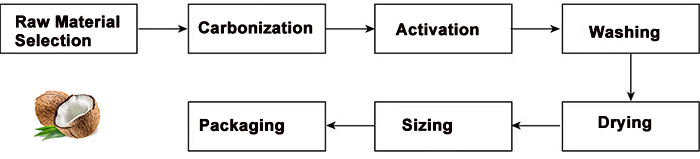

How do you make active carbon?

Here's a general process of making activated carbon:Raw Material Selection: Various carbon-rich materials can be used, such as wood, coconut shells, peat, coal, or sawdust. Coconut shells are a popular choice due to their high porosity.

Carbonization: The selected raw material is heated at high temperatures (500-900 degrees Celsius) in an oxygen-limited environment, which drives off volatile compounds and leaves behind mostly carbon. This process is called carbonization and transforms the material into char.

Activation: The char is then activated through one of two methods:

a. Chemical Activation: The carbonized material is treated with chemicals like phosphoric acid, potassium hydroxide, or zinc chloride. This chemical treatment creates pores in the carbon by removing some of the carbon atoms, thereby increasing its surface area. After impregnation, the material is heated again to high temperatures to activate it.

b. Physical Activation: In this method, the carbonized material is exposed to high temperatures (800-1100 degrees Celsius) and an oxidizing gas, such as steam or carbon dioxide, in a controlled environment. This process opens up pores by gasifying parts of the carbon, leaving behind a highly porous structure.

Washing and Drying: The activated carbon is then washed to remove any remaining impurities or chemicals used in the activation process. It is typically washed with water or acid and then dried thoroughly.

Sizing and Packaging: The activated carbon is often crushed or ground into different particle sizes, depending on its intended use. It can be formed into granules, pellets, or powdered form before packaging.

It's important to note that the specific method of creating activated carbon might vary depending on the manufacturer, the intended use, and the properties desired for the final product. Additionally, safety precautions should be taken when working with high temperatures and chemicals during the production process.