Nowadays, in the process of urbanization, exhaust gas and odor are a major problem of environmental quality. As we all know, exhaust gas odor not only causes harm to human health, but also causes pollution to the environment. Therefore, how to effectively remove exhaust gas odor has become a very important issue.

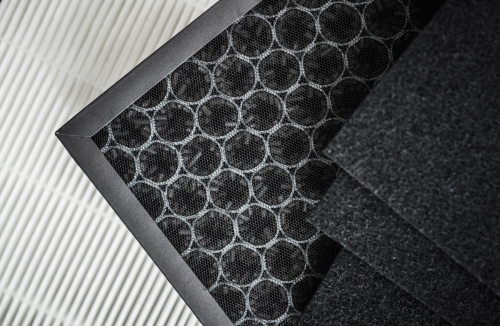

As an environmentally friendly material, activated carbon can effectively remove odors from exhaust gas. It has the characteristics of large specific surface area, high adsorption performance, and not easy to wear. It can adsorb odorous substances in exhaust gas to achieve the purpose of purifying the air. Moreover, the nature of activated carbon determines that it can react chemically with oxygen and water to generate stable and harmless carbon dioxide and water.

Activated carbon has good environmental protection properties and is suitable for various fields. Among them, the removal of exhaust gas odor is one of the most prominent applications. Moreover, with the continuous advancement of science and technology, the performance and application of activated carbon will become more and more extensive.

.jpg)

How does activated carbon remove Odour?

Activated carbon, also called activated carbon adsorbent, is an excellent adsorption material with strong adsorption capacity. It can absorb odors, organic matter, color, moisture, etc. in the air, so it is widely used in air purification, water treatment, food processing and other fields.The principle of activated carbon adsorbing odor is the result of the combination of physical adsorption and chemical adsorption. Physical adsorption refers to the attachment of substances to the surface to form electrostatic adsorption and van der Waals force adsorption, while chemical adsorption refers to the chemical reaction of covalent bonds between substances on the surface. Activated carbon has a large surface area, so there are many air molecules attached to the surface, thereby adsorbing odors.

In addition, activated carbon also has three pore sizes: micropores, mesopores and macropores, which can adsorb different molecular sizes. For example, some macromolecular organic compounds are adsorbed through mesopores, while small molecule organic compounds are adsorbed through micropores. In this way, activated carbon can remove odors more efficiently and make the environment more comfortable.

The strong adsorption capacity of activated carbon is due to its large surface, structure with different pore sizes, and the synergistic effect of physical and chemical adsorption mechanisms. Therefore, it is a very excellent adsorption material and is widely used in life and industry.

.jpg)

How often should activated carbon be replaced?

Exhaust gas adsorption activated carbon is a commonly used air purification material, which has the function of adsorbing, decomposing and filtering harmful gases in the air. However, as the use time increases, its adsorption capacity will gradually decrease and it needs to be replaced in time.So, how to judge the replacement time of waste gas adsorption activated carbon? First of all, the replacement cycle must be determined according to the use environment and gas type. For example, in a highly polluted environment, the replacement cycle should be shorter. Generally speaking, it is recommended to replace it every 3-6 months to avoid excessive pollution caused by no decrease in adsorption capacity during use.

In addition, you also need to pay attention to the conditions of use. For example, if used in a humid environment, the life of the waste gas adsorption activated carbon will be greatly shortened, so it needs to be checked and replaced regularly. At the same time, avoid long-term non-use or storage to prevent the adsorbent from getting damp or gradually deactivating, which will affect its performance.

To sum up, the replacement time of waste gas adsorption activated carbon should be determined according to the specific use environment and gas type, and should be replaced regularly under normal use conditions to ensure its adsorption effect and service life.

What is the efficiency of activated carbon?

Activated carbon is an efficient exhaust gas treatment material that can be used to remove harmful gases and odors. Its treatment efficiency depends on its surface area and pore structure.Activated carbon has a large surface area because it has a large number of micropores and mesopores. These pores provide a large surface area for contaminant molecules to attach to its surface. In addition, activated carbon also has good adsorption properties and can adsorb different types of harmful gases, such as ammonia, formaldehyde, etc.

The efficiency of using activated carbon to treat exhaust gas mainly depends on the following factors:

The first is the type and quality of activated carbon. Different types of activated carbon have different physical and chemical properties, so their adsorption properties are also different. High-quality activated carbon removes contaminants better than ordinary activated carbon.

The second is the thickness and porosity of activated carbon. The higher the porosity of activated carbon, the greater the adsorption capacity of pollutants. However, if a large amount of waste gas is to be treated, a thicker activated carbon needs to be used. This ensures that the activated carbon absorbs waste gas for a longer period of time and improves treatment efficiency.

The last step is to treat the temperature and flow rate of the exhaust gas. The adsorption capacity of activated carbon is affected by temperature and pressure, so it needs to be adjusted according to the specific situation.

In conclusion, the efficiency of activated carbon in treating exhaust gas is high. To give full play to the treatment capabilities of activated carbon, choosing high-quality activated carbon and appropriate parameters are necessary.