What is the use of activated carbon in sugar industry?

The original syrup has a brown or yellow color, while the appearance of white sugar requires white or milky white color, so it needs to be decolorized. And pigments and impurities in syrup often affect the quality and taste of food and beverages. In order to remove these impurities, activated carbon is often applied to decolorize syrup during the production process.

Activated carbon is an adsorbent material with a highly porous structure and surface activity. Its main component is carbon, which has a large number of micropores and mesoporous structures, and has extremely high specific surface area and porosity. Due to these characteristics, activated carbon plays an important role in the decolorization process of syrup. It can effectively absorb pigments, proteins, impurities and other organic substances in the syrup, thereby achieving decolorization of the syrup.

What kind of carbon is used for refining sugar?

In the sugar industry, wood activated carbon or agglomerated activated carbon is generally used. These activated carbons are more likely to adsorb organic matter and are relatively cheap. Generally, activated carbon is decolorized under high temperature and high pressure conditions, which can not only enhance its adsorption capacity, but also remove impurities as much as possible. It can also reduce the content of organic matter in syrup, thereby improving the purity and quality of sugar. How does decolorizing carbon work? The function of activated carbon is to adsorb the pigments and impurities in the syrup to its surface through physical adsorption and fix them in the pores of the activated carbon, making the color of the syrup transparent without affecting its taste.

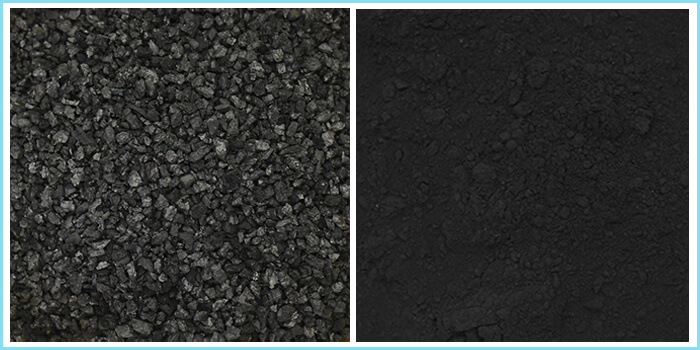

Wood Activated Carbon & Agglomerated Activated Carbon

| Item | Wood Activated Carbon Powder | Agglomerated Activated Carbon |

| Size | 200mesh, 325mesh | 12*40mesh |

| Iodine value | 900-1200mg/g | 900-1100mg/g |

| Methylene blue | 150-300mg/g | 210min |

| Moisture | ≥10% | ≤5% |

| Ash | ≤8% | ≤10% |

| The difference | ||

| Wood Activated Carbon Powder | 1. It is suitable for rapid decolorization, especially effective for pigments and large organic molecules. 2. Typically added directly to the sugar solution, stirred, and then filtered. |

|

| Agglomerated Activated Carbon | 1. It is a slower adsorption rate, suitable for long-term decolorization, and better for pigments and small organic molecules. 2. Mostly used in fixed-bed or fluidized-bed adsorption systems, where the sugar solution passes through the carbon bed for decolorization. |

|

During the decolorization process, the syrup passes through the bed of activated carbon. As the syrup gradually passes through the activated carbon bed, the pigments and impurities in it are adsorbed and fixed in the activated carbon. Activated carbon has different adsorption capabilities for different types of pigments and impurities. Therefore, the type and amount of activated carbon selected need to be adjusted according to the types of impurities and pigments contained in the syrup.

What is the process of decolorization?

Step 1: Prepare sugar solution and high-quality activated carbon.

Step 2: Put activated carbon into the sugar solution and stir evenly; the amount of activated carbon added is generally 1% to 3% of the volume of the sugar solution. When using activated carbon to remove color in sugar production, the appropriate input amount is very critical. If too much is put in, part of the sugar will be adsorbed, resulting in a decrease in sugar yield and affecting the quality of sugar. If the input is insufficient, the required decolorization effect cannot be achieved.

Step 3: Let it sit for a period of time. The standing time should be long enough to give full play to the adsorption effect of activated carbon and fully absorb pigments and turbid substances.

Step 4: After decolorizing the sugar solution, filter the sugar solution with filter paper or a sieve to remove activated carbon and adsorbed substances.

Notes of decolorizing process:

1. Before adding activated carbon, the sugar solution can be heated to 60℃~70℃ to speed up the decolorization.

2. For darker-colored sugar liquid, it needs to be decolorized multiple times to achieve the desired effect.

3. If the sugar liquid contains acidic substances, alkaline activated carbon should be used; if the sugar liquid contains alkaline substances, acidic activated carbon should be used.

4. Before decolorizing the sugar solution, precipitation treatment can be performed to remove large particles.

5. Used activated carbon cannot be reused and should be replaced in time.

Conclusion

In the white sugar decolorization process, activated carbon plays an indispensable role. From candies to beverages, activated carbon is widely used in the production of food products, bringing unparalleled quality and taste experience to consumers. Want to learn more about activated carbon and how to apply it in your production process? Contact Zhulin Activated Carbon immediately, we will provide you with professional solutions and services.