Activated carbon is a black, porous powder or granules that lacks odor and taste. It exhibits stable chemical properties at room temperature and remains insoluble in water and common solutions. The apparent density of activated carbon varies significantly depending on the raw materials and production methods. Its structure consists of interconnected pores, both vertically and horizontally, with pore diameters ranging from 0.1 to 100.0 nm, especially in the range of 0.1 to 1.0 nm. These pores contribute to a substantial micropore surface area, with a total area exceeding 1000 m²/g. This physical characteristic plays a crucial role in its exceptional capacity to adsorb organic matter. Consequently, activated carbon is a highly effective adsorbent commonly used in the food industry for the decolorization of edible oils. This process involves the removal of impurities and pigments that can negatively impact the appearance, taste, and shelf life of the oil.

Activated Carbon in Oil Refining Application

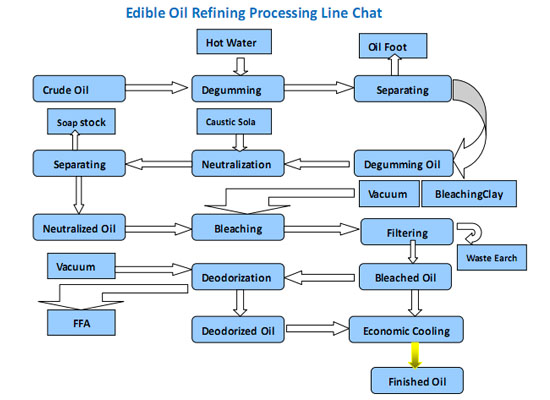

The main component of cooking oil is fat, that it, fatty acid glyceride, also contains a small amount of free fatty acids and other impurities. There are usually three steps in the refining oil method: neutralization, decolorization, and deodorization. After refining the oil, remove harmful ingredients and retain beneficial ingredients.

Neutralization generally uses sodium hydroxide to remove free fatty acids, and also has the function of removing proteins and gums, and reduces other impurities. If you want to change the color of the oil to monochrome, you need to do further processing. Usually, activated clay and powdered activated carbon are used in combination to achieve the effect of decolorization and oil purification.

Activated carbon for decolorization

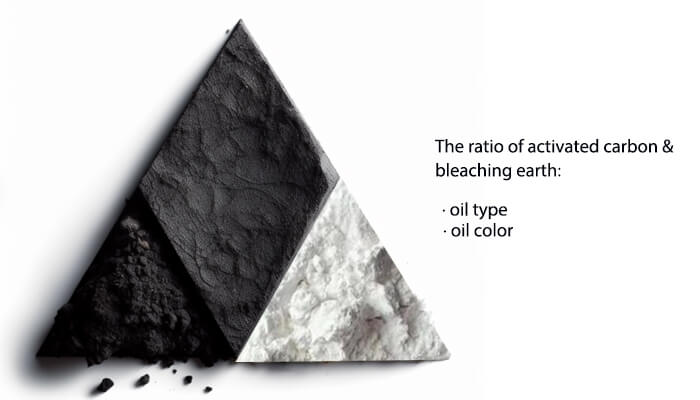

Activated carbon possesses porous structure with loose pores, resulting in a large specific surface area and excellent decolorization coefficient. Additionally, it exhibits hydrophobic properties, enabling it to effectively absorb polymer substances. Besides, activated carbon excels in the removal of blue and green pigments and can also eliminate grease residue caused by trace mineral oils.In comparison to activated clay, activated carbon offers distinct advantages in oil decolorization. It yields oil with a lower red value, resulting in superior decolorization effects, while typically avoiding any unwanted odors in the processed oil. However, activated carbon is relatively costly, and high oil absorption rate leads to slower filtration speed after decolorization.

Therefore, it is commonly employed with bleaching earth, with a typical mixing ratio of 1: (10~20). This combined approach significantly enhances decolorization capabilities and effectively eliminates any residual odors associated with the bleaching earth.

Activated Carbon for Benzopyrene

Benzopyrene is a strong carcinogen. It is a polycyclic aromatic hydrocarbon composed of 5 benzene rings. It is a colorless to light yellow needle-like crystal at room temperature. It is stable and insoluble in water. It is slightly soluble in ethanol, methanol, etc. in organic solvents. "Hygienic Standards for Edible Vegetable Oil" stipulates that the content of benzopyrene in edible vegetable oil is ≤10μg/Kg; the EU limit standard is 2.0μg/Kg.

Benzopyrene is a strong carcinogen. It is a polycyclic aromatic hydrocarbon composed of 5 benzene rings. It is a colorless to light yellow needle-like crystal at room temperature. It is stable and insoluble in water. It is slightly soluble in ethanol, methanol, etc. in organic solvents. "Hygienic Standards for Edible Vegetable Oil" stipulates that the content of benzopyrene in edible vegetable oil is ≤10μg/Kg; the EU limit standard is 2.0μg/Kg.Benzopyrene in vegetable oil primarily originates from the following sources:

- Air pollution during the cultivation of raw materials.

- Sun-drying of raw materials on asphalt roads and storage in chemical containers.

- High-temperature drying and stir-frying during pressing pretreatment.

- Oil leakage and high-temperature heating without vacuum protection.

Activated carbon can be prepared from a variety of carbon-containing raw materials (coal, wood, fruit shell, etc.), after high temperature treatment, and then activated by chemical activators (phosphoric acid, zinc oxide, etc.), air, and steam to increase its surface area and improve adsorption activity .

Activated carbon can effectively remove high molecular weight PAHs that cannot be adsorbed by white clay (while the deodorization process can only remove low molecular weight PAHs containing 4 or less). Activated carbon is particularly strong in adsorption of PAHs, and even by pressing the activated carbon filter cake, the filtered oil does not contain PAHs.

Conclusion about activated carbon for oil decolorization

The decolorization of edible oil is also important for the selection of activated carbon. The activated carbon products produced by different activation methods are also different. It is suitable for the decolorization of different oils. It is generally better to conduct experiments before usage. The pH of activated carbon is also very important, controlled between 5-8, too alkaline or too acidic will cause undesirable changes in edible oil.

Our experts can help you choose the most efficient and cost-effective purification solutions for your edible oil processing operation.