Spray booths are essential facilities in automotive, furniture, aerospace, and industrial coating operations. While they provide controlled environments for painting and coating applications, they also generate significant amounts of volatile organic compounds (VOCs), overspray particles, and hazardous air pollutants. Effective air filtration is not just a regulatory requirement—it's crucial for worker safety, environmental protection, and operational efficiency.

Activated carbon filtration has become a regular method for VOC removal of spray booths. And pellet & honeycomb activated carbon is prefered choosen. Here the blog explores these two types of activated carbon for this application.

Understanding Spray Booth Emission

.png)

Spray booth operations create a complex mixture of air contaminants:

Volatile Organic Compounds (VOCs): Paint solvents like toluene, xylene, acetone, and ethyl acetate evaporate during the spraying and curing processes. These compounds constitute 40-70% of paint formulations by volume and represent the primary target for activated carbon filtration.

Overspray Particulates: Fine droplets of paint that don't adhere to the target surface become airborne particles. While pre-filters typically capture these, some fine particles (below 10 microns) can reach carbon filters, potentially reducing their effectiveness.

Mixed Solvent Streams: Unlike single-chemical industrial processes, spray booths emit dozens of different VOCs simultaneously. Your activated carbon must have broad-spectrum adsorption capability to handle this diversity.

Pellet Activated Carbon for Spray Booths

What is Pellet Activated Carbon?

Pellet activated carbon consists of cylindrical extruded particles created by combining carbonaceous materials (typically coal, coconut shell, or wood) with a binder, extruding the mixture through dies, and then activating it at high temperatures (800-1,000°C). The result is uniform, durable cylindrical pellets with excellent mechanical strength and predictable performance characteristics.

Pellet activated carbon parameter

|

Size |

4± 0.5 mm |

|||

|

Iodine Number |

900-1,100 mg/g |

|||

| CTC | 60-80% | |||

|

Surface Area |

1,000-1,200 m²/g |

|||

| Bulk density | 450-550 kg/m³ | |||

|

Hardness |

≥95% |

|||

|

Ash content |

≤8% (coal-based) or ≤3% (coconut shell) |

|||

|

Moisture |

≤5% |

|||

Performance Parameters:

Adsorption Capacity: 25-35% by weight for typical paint solvents (toluene, xylene, acetone)

Working Capacity: 15-25% in actual service conditions (accounting for humidity, mixed VOCs, and competitive adsorption)

Honeycomb Activated Carbon for Spray Booths

What is Honeycomb Activated Carbon?

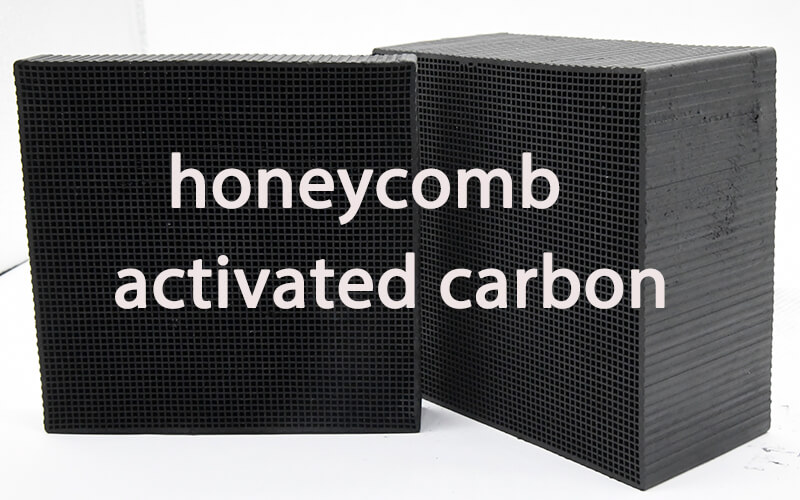

Honeycomb activated carbon represents an innovative form factor where activated carbon is structured into a monolithic block containing hundreds of parallel channels, similar to a catalytic converter. The structure resembles a honeycomb, with square, hexagonal, or triangular cells running through the entire block length.

Manufacturing Process:

The creation of honeycomb activated carbon involves sophisticated manufacturing:

- Powder Preparation: Activated carbon powder is mixed with binders (typically clay, cellulose, or synthetic polymers) and water to form a plastic paste

- Extrusion: The paste is forced through precision dies containing hundreds of pin arrays that create the honeycomb channel structure

- Drying: Extruded blocks are carefully dried to remove moisture while maintaining structural integrity

- Carbonization: Blocks are heated to 400-600°C in oxygen-limited environment to carbonize binders

- Activation: Steam or CO₂ activation at 800-900°C develops porosity and surface area

- Quality Control: Blocks are inspected, measured, and tested for adsorption properties

The result is a rigid, self-supporting structure that combines activated carbon's adsorption properties with excellent airflow characteristics.

Standard Specifications for Spray Booth Applications

Physical Structure:

Block Dimensions:

- Standard Block Size: 100×100×100 mm (most common), also available in 150×150×100 mm

- Wall Thickness: 0.4-1.0 mm (thinner walls provide more open area, thicker walls provide strength)

- Cell Density: 100-400 cells per square inch (CPSI)

- 100 CPSI: Lower pressure drop, lower surface area per volume

- 200 CPSI: Industry standard for spray booth applications

- 300-400 CPSI: Maximum surface area, higher pressure drop