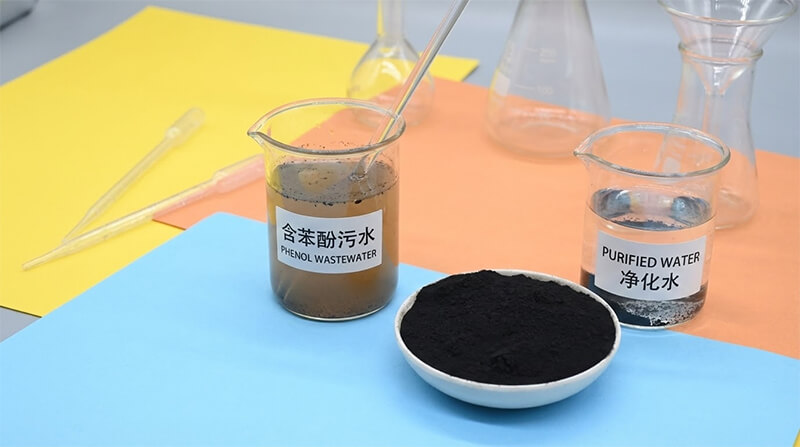

One of the most widely used technologies is activated carbon adsorption. With its high surface area, well‑developed microporous structure, and strong affinity for aromatic compounds, activated carbon is an ideal material for removing phenol from water.

Why Activated Carbon Works Well for Phenol Removal

Phenol molecules are aromatic and hydrophobic, making them strongly attracted to the micro‑pores of activated carbon. Several factors make activated carbon highly effective:

• High surface area (typically 900–1100 m²/g)

• Large micropore volume suitable for phenolic molecules

• Strong π–π interactions between carbon surface and phenol

• Fast adsorption kinetics, especially with powdered activated carbon

• Safe, stable, and easy to operate in existing treatment systems

As a result, activated carbon can remove phenol efficiently even at low concentrations, making it suitable for polishing treatment.

Types of Activated Carbon Used for Phenol Removal

Different forms of activated carbon offer different performance characteristics:1. Powdered Activated Carbon (PAC)

• Best for rapid treatment

• Easily mixed into wastewater

• High removal efficiency within 20–60 minutes

• Suitable for emergency treatment or high-load phenol waste

2. Granular Activated Carbon (GAC)

• Used in fixed beds or continuous treatment systems

• Long service life and regenerable

• Suitable for industrial refineries, chemical plants, and centralized wastewater treatment

3. Extruded Activated Carbon (EAC)

• Low pressure drop

• Excellent for gas purification and combined vapor–liquid applications

For phenol wastewater, PAC and GAC are the most common choices.

Key Performance Indicators for Phenol Adsorption

Customers often evaluate activated carbon using several technical parameters:

1. Phenol adsorption capacity

Typical capacity ranges from 120–250 mg/g, depending on pore structure.

2. Iodine value

Higher iodine value (900–1100 mg/g) generally means better performance.

3. Pore size distribution

Micropores (0.5–2 nm) are crucial for phenol adsorption.

4. Breakthrough time (for GAC systems)

Depends on inlet concentration, empty bed contact time (EBCT), and carbon quality.

5. pH and temperature

Phenol adsorption is optimal at pH 5–7.

Lower temperatures improve adsorption efficiency.

Operating Conditions That Improve Phenol Removal Efficiency

To achieve the best results, industries should consider the following:pH: Slightly acidic conditions improve adsorption.

Dosage (PAC): 5–25 g/L depending on phenol concentration.

Contact time: 20–60 minutes for PAC; EBCT 6–12 minutes for GAC.

Pretreatment: Remove suspended solids to avoid pore blockage.

With proper operating conditions, activated carbon can reach over 90% phenol removal efficiency.

Applications of Activated Carbon in Phenol-Contaminated Wastewater

Activated carbon is widely used in:• Petrochemical industry effluent

• Pharmaceutical production wastewater

• Resin and plastic manufacturing

• Coking and coal industry

• Landfill leachate

• Final polishing after biological treatment

Because activated carbon can handle fluctuating concentrations and complex chemical mixtures, it is often the final step to meet discharge standards.

Conclusion

Activated carbon remains one of the most effective and economical approaches for removing phenol from wastewater. Its versatility, strong adsorption performance, and ability to integrate with existing systems make it suitable for both small and large industrial applications.If you need product recommendations, performance data, or a tailored solution for your phenol wastewater, feel free to contact us.