Introduction

MSG, also known as monosodium glutamate, is a common condiment in food and cooking, but the MSG is obtained after decolorization and purification of the MSG mother liquor. The ingredients in the MSG mother liquor are relatively complex, with protein colloids, organic substances, inorganic ions, and pigments being the main ingredients. Therefore, in the production process of MSG, activated carbon is often used to decolorize and deodorize raw materials. This blog presents MSG production process and the detailed application of activated carbon for MSG.

MSG production process

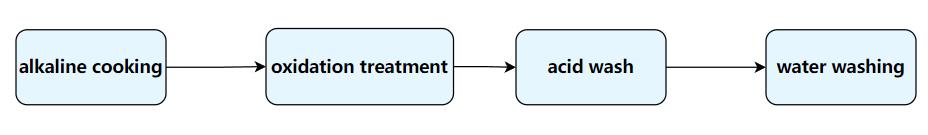

The following is the detailed production process of MSG:

Alkaline cooking

Washing the MSG mother liquor with alkaline NaOH solution can bring part of the pigment and most of the protein colloids to the water phase outside the activated carbon, or use organic substances such as phenols and acids to turn them into salts that are easily soluble in water. However, when performing alkali boiling, try to control the temperature during filtration to a higher range, generally above 80°C.Oxidation treatment

(The amount of H2O2 is 3%, the amount of co-oxidant is 2.2%, and the amount of catalyst is 0.1%) The purpose of oxidation treatment is to remove impurities that have not been washed away after alkali boiling. These impurities are impurities that can form relatively strong chemical bonds with the functional groups on the surface of activated carbon. These chemical bonds can be solved through oxidation treatment. The use of hydrogen peroxide, an oxidizing agent with moderately strong oxidizing properties in a neutral or alkaline solution, and a certain amount of catalyst can greatly improve the reaction effect.Acid wash (4%HC1 lotion)

After the waste carbon is boiled with alkali and oxidized. After decolorizing the MSG mother liquor, the transmittance is between 85% and 95%. If HC1 is used to remove impurities such as inorganic ions in the activated carbon, the transmittance can generally reach more than 95%.Water wash

Water washing and filtration can not only extend the service life of activated carbon for MSG decolorization, but also make the decolorization ability slightly better.How to use activated carbon for monosodium glutamate?

Choosing the right activated carbon

Different types and specifications of activated carbon have different adsorption capabilities and effects on different impurities and organic molecules. Therefore, it is necessary to select the appropriate activated carbon based on actual needs and production processes.Adding amount of activated carbon

The amount of activated carbon added is generally 3%-5% of the MSG raw material, which needs to be adjusted according to the actual situation. Adding too much will increase cost of MSG t, while adding too little will not achieve the desired effect.Activated carbon treatment time and temperature

The treatment time and temperature of activated carbon are also important factors that affect the adsorption effect. Generally, the treatment time is 3-4 hours and the treatment temperature is 60-70°C. It should be noted that constant stirring and turning are required during the treatment process to ensure that the MSG evenly contacts the activated carbon and improve the adsorption efficiency.Conclusion

In short, activated carbon is a very important purification and separation material and also plays an important role in MSG production. By correctly selecting activated carbon, controlling the amount of activated carbon added and processing conditions, the quality and taste of MSG can be effectively improved to meet the needs of consumers.

Zhulin Carbon, with its regenerability and compliance with food safety regulations, make it a sustainable and reliable choice for MSG manufacturers seeking consistent quality and consumer satisfaction. Whether customizing solutions to specific production processes or providing standard products, Zhulin Carbon remains a trusted partner in the pursuit of excellence in MSG purification.

Zhulin Carbon, with its regenerability and compliance with food safety regulations, make it a sustainable and reliable choice for MSG manufacturers seeking consistent quality and consumer satisfaction. Whether customizing solutions to specific production processes or providing standard products, Zhulin Carbon remains a trusted partner in the pursuit of excellence in MSG purification.